A Reliability Assessment Tool For NDT Inspection Systems

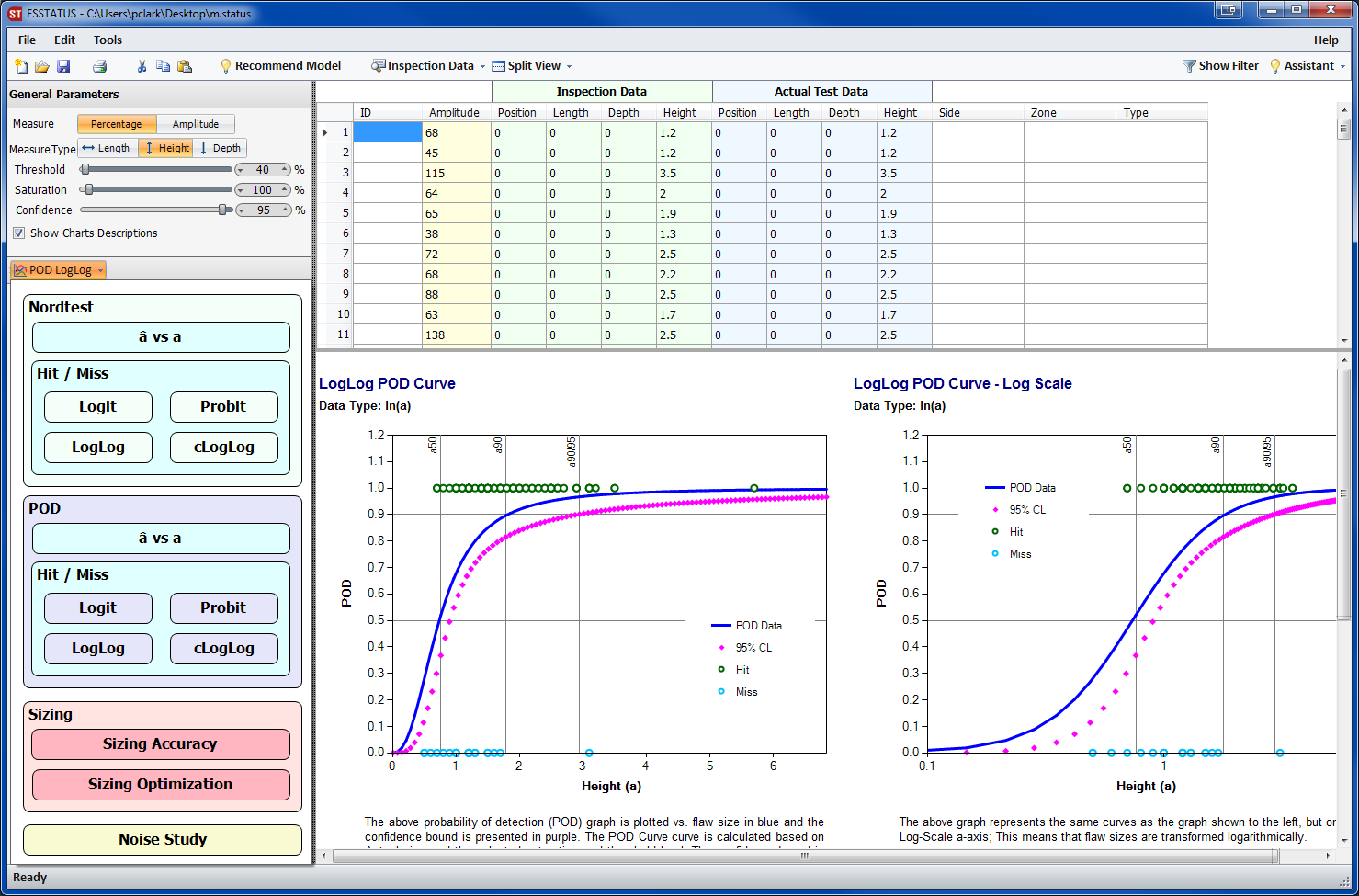

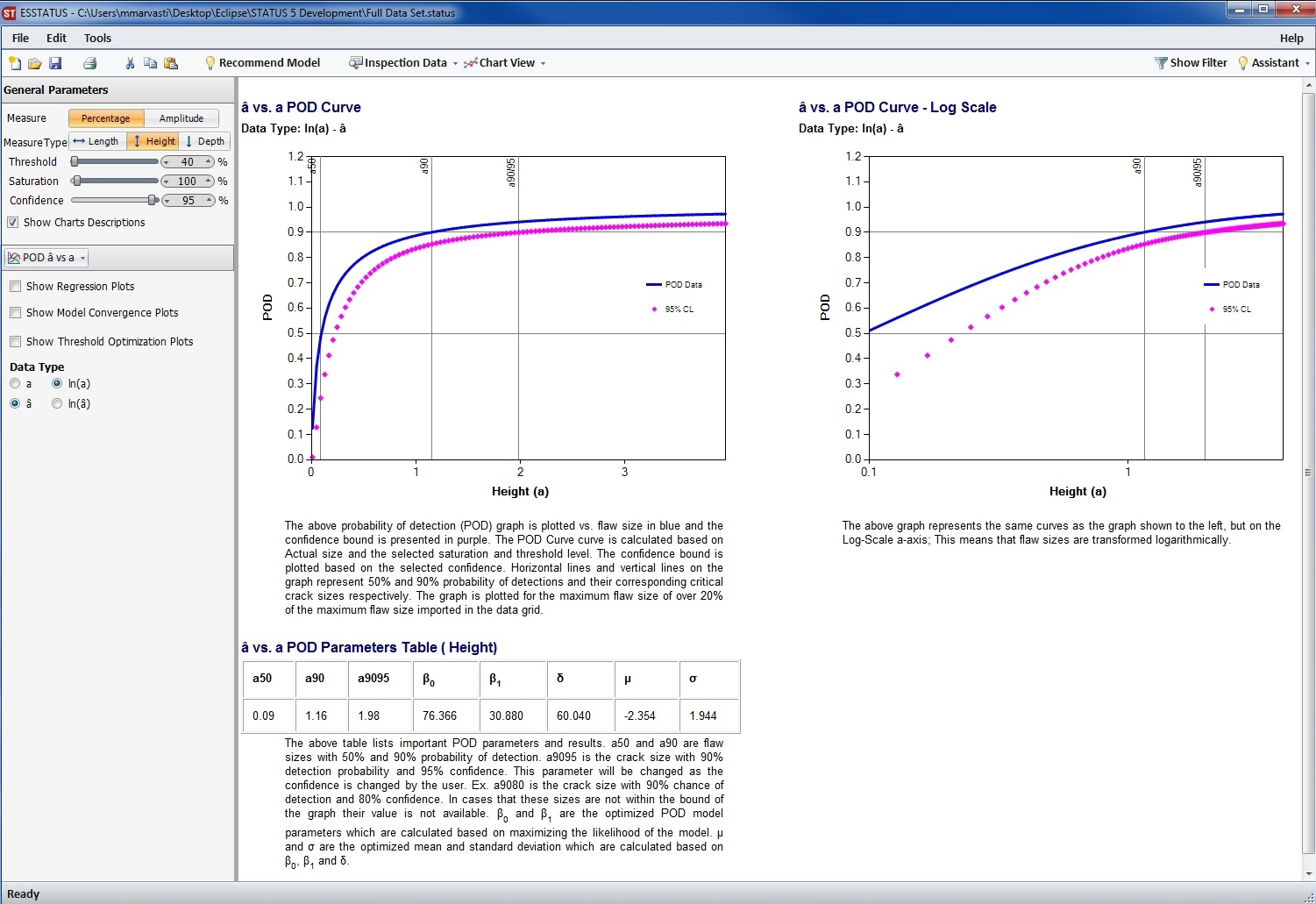

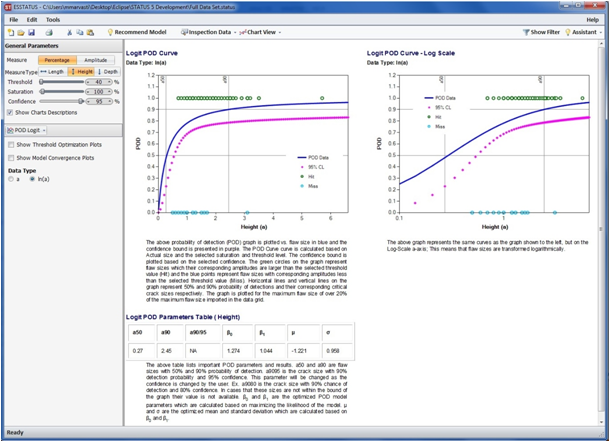

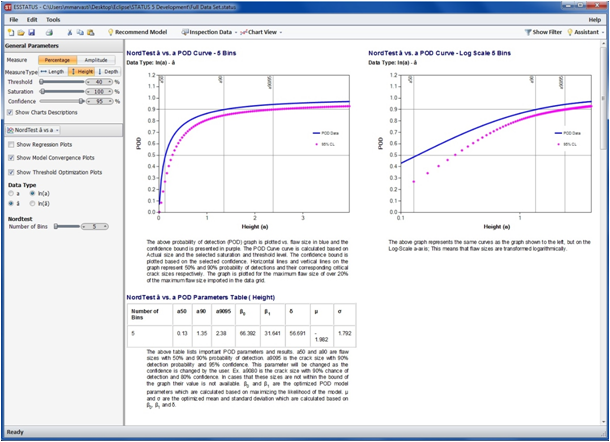

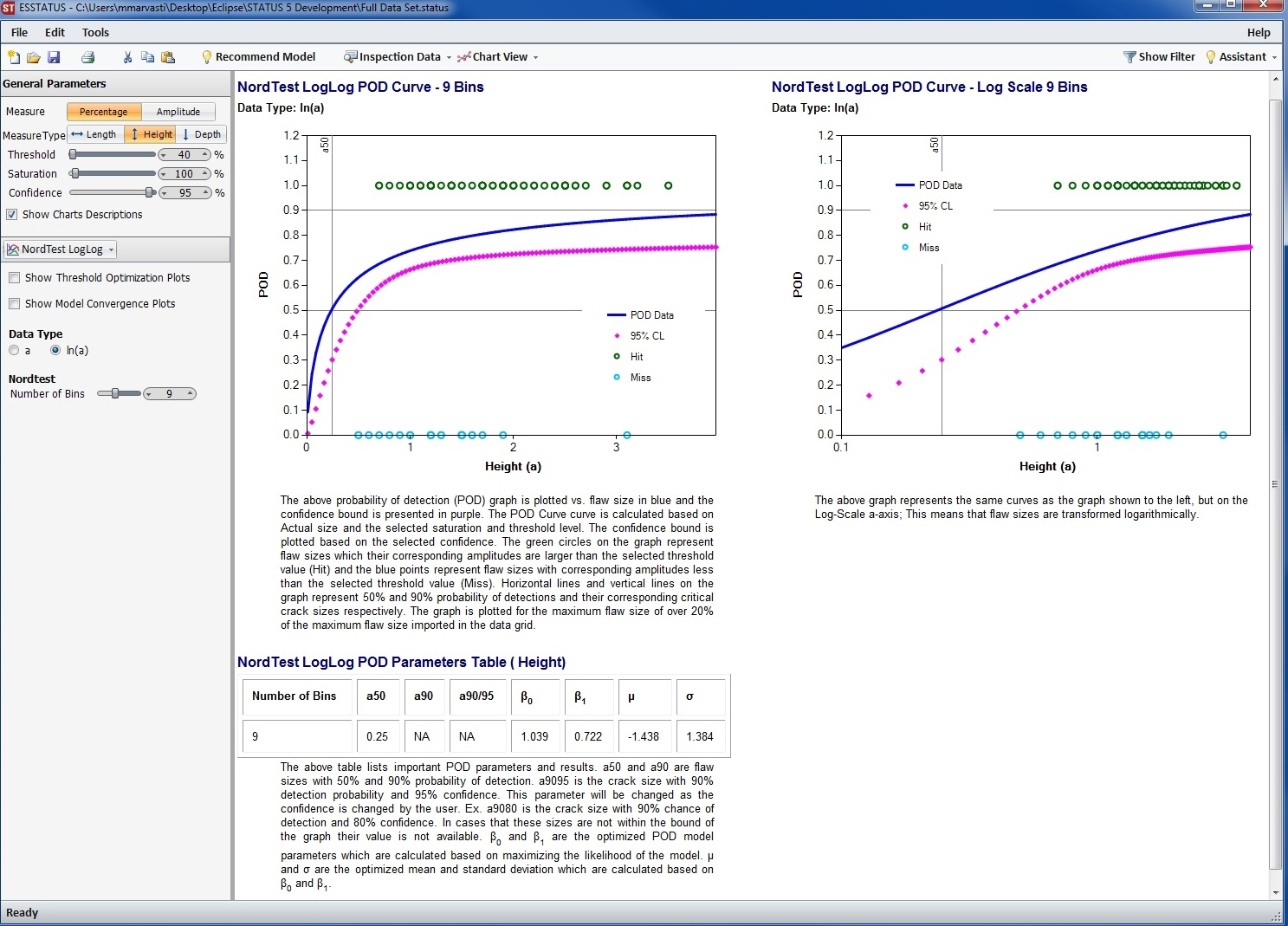

STATUS 5 measures the reliability of an inspection system to detect specified flaw sizes based on statistical analysis of imported data. The user-friendly software is an essential NDT tool for generating Probability of Detection (POD) curves, optimization plots and summary tables, tailored for technicians with a limited knowledge of statistics.

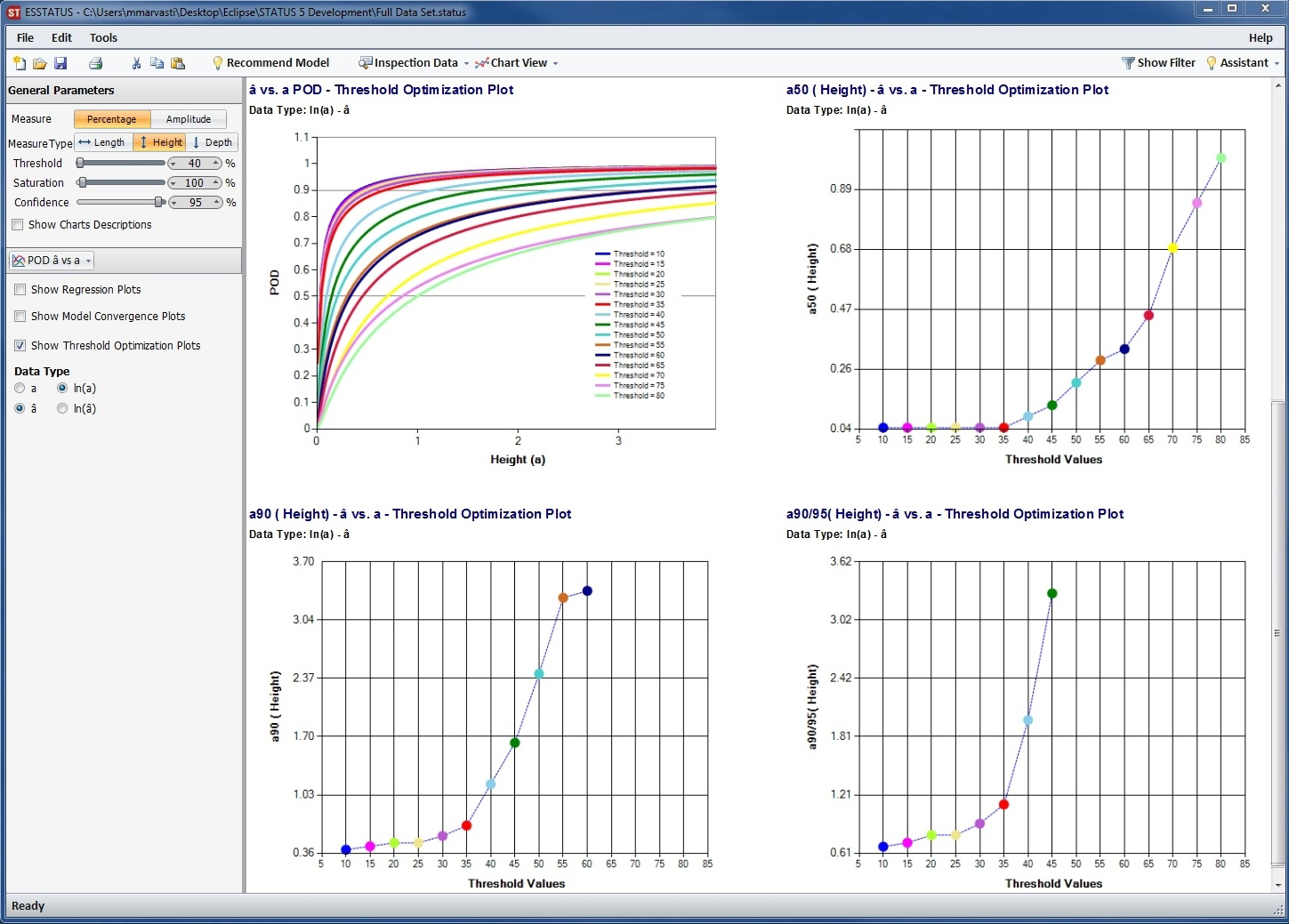

Driven by an intuitive user-friendly interface, Status 5 instantly generates visualized data as POD curves using the statistical analysis methods of â vs. a, Logit, Probit, LogLog, CLogLog and Nordtest Models.

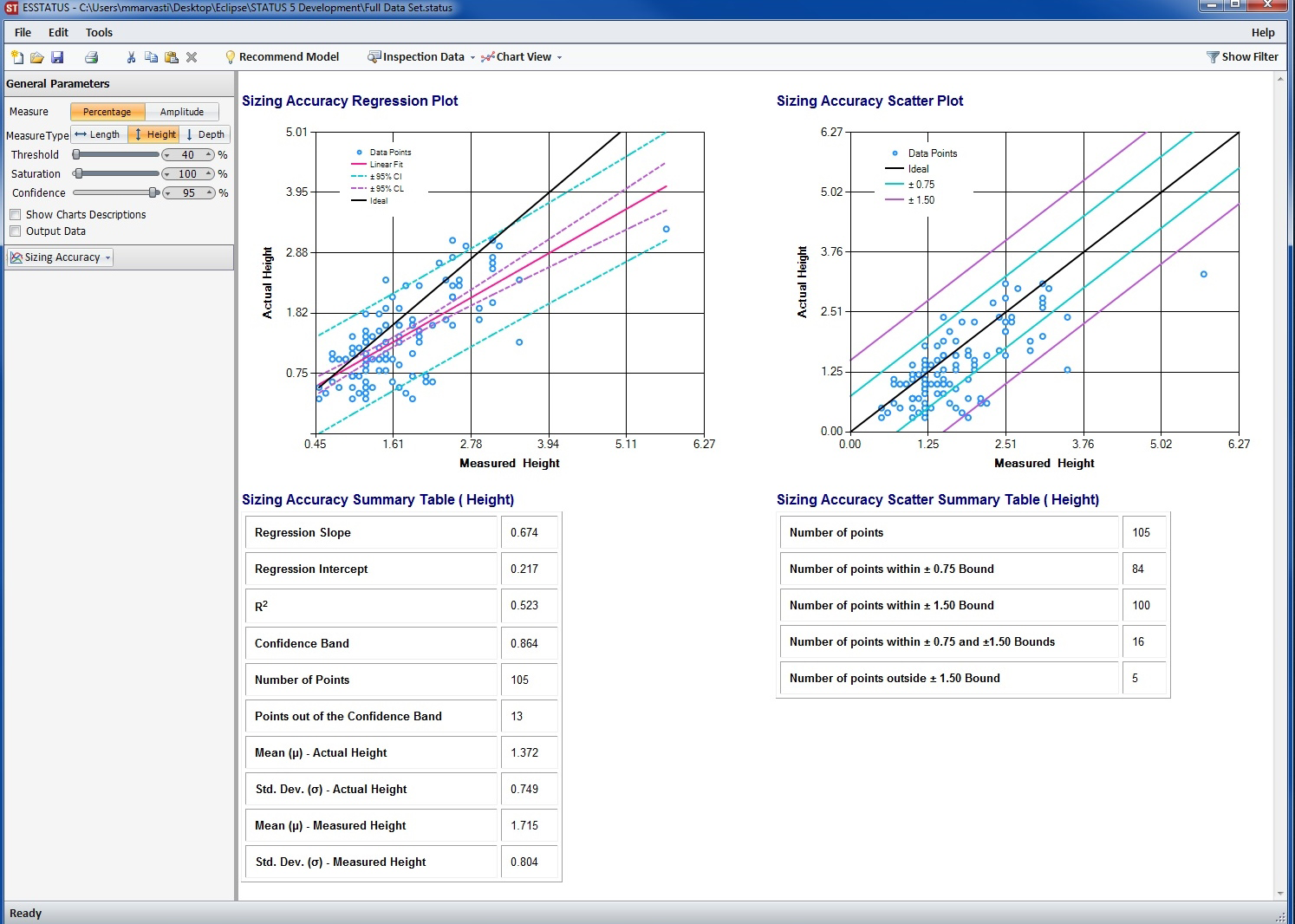

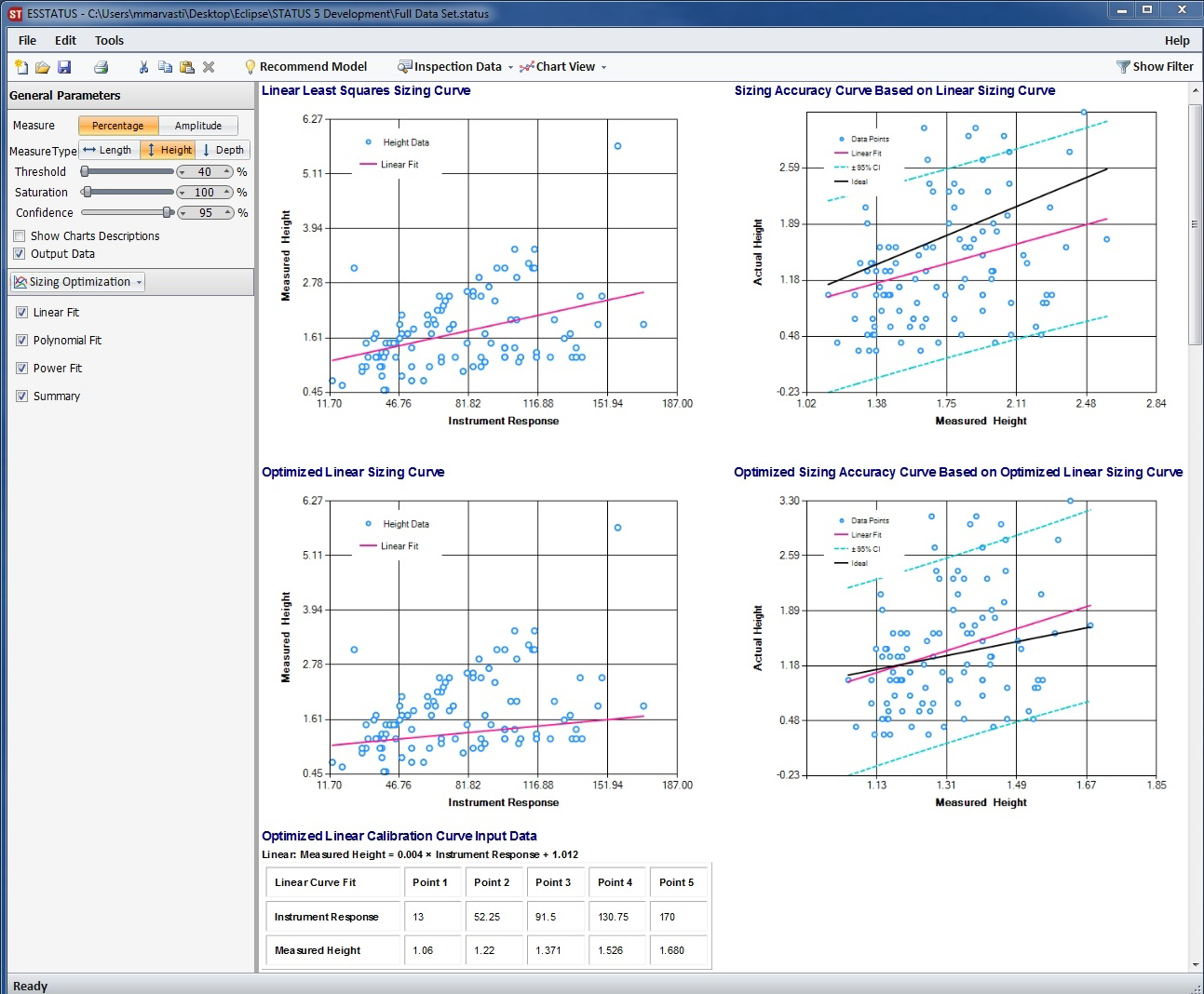

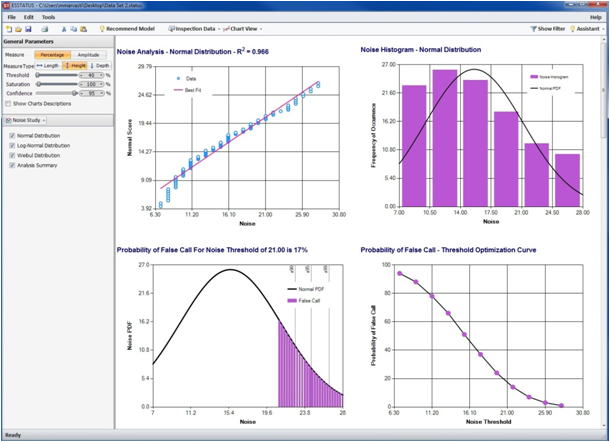

Users can optimize input and compensate for system noise with minimal statistical knowledge using the Noise Study and Threshold Optimization Tools. Status 5 also includes Sizing Accuracy and optimization tools to calculate flaw sizing capabilities and provide assistance.

For more information, email us at

pod@eclipsescientific.com

or call (519) 372-1831 and ask for

Status Support