Application Based On Auto Highlighting Scan Data Anomalies

Anomaly Detection Based Applications

- Corrosion Under Pipe Support (Robust Detection/Screening)

- Tank Floor Inspection from outside Chime (Robust Detection/Screening)

- Sleeve Weld Inspection (Complex Geometries)

- Vessel Inspection at Elevated Temperatures

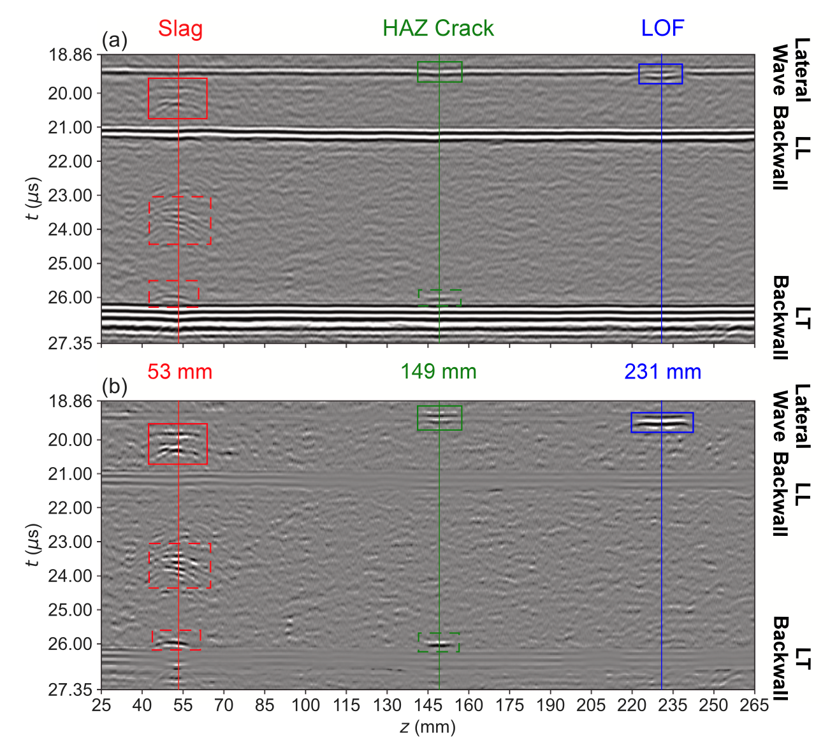

Anomaly Detection Approach to Representing UT Data

- Only Highlighting indications which are ”unusual” compared with the rest of the scan (Shannon Information Processing)

- Ideal for highlighting subtle damage signatures, especially when close to specimen boundaries e.g. shallow cracks

- Subject of recent publication by ADG

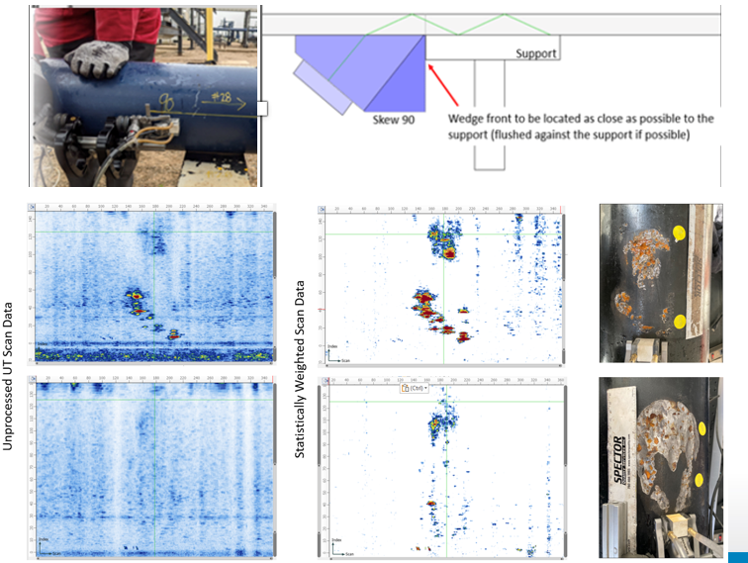

Shannon Information Processing: Corrosion Under Pipe Support (CUPS)

- Multiple skip phased array inspection can be used to detect corrosion under pipe supports (without lifting pipe)

- Smoothly texture, deep flaws do not reflect ultrasound well, easily missed

- Shannon information (statistical processing) finds weak reflections by comparing to area off of support

- Robust tool for screening/detection of Corrosion Under Pipe Supports

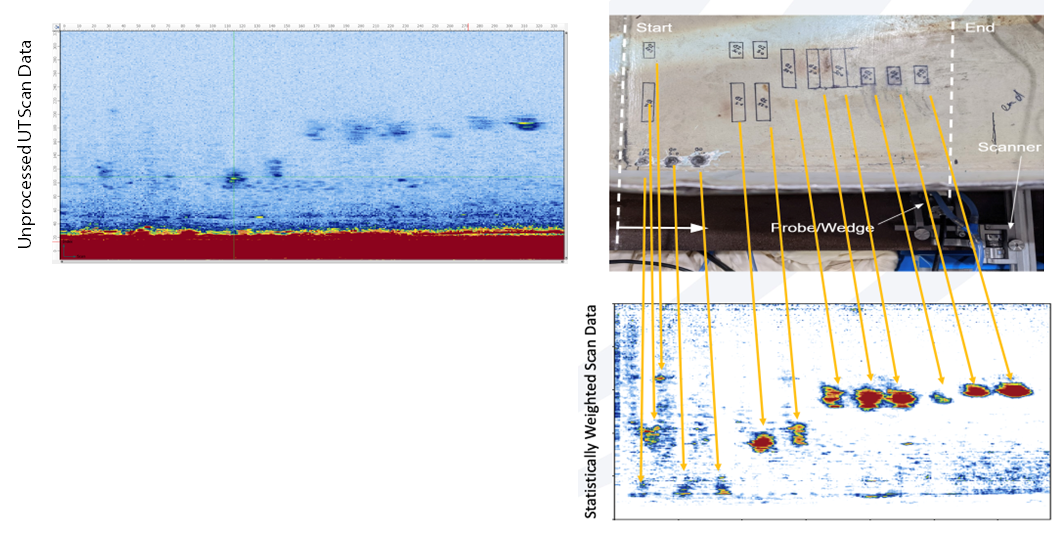

Shannon Information Processing: Tank Floor Inspection

- Multiple skip phased array inspection can be used to detect corrosion in annular ring plate of storage tanks

- Smoothly texture, deep flaws do not reflect ultrasound well, easily missed

- Shannon information (statistical processing) finds weak reflections with greater confidence

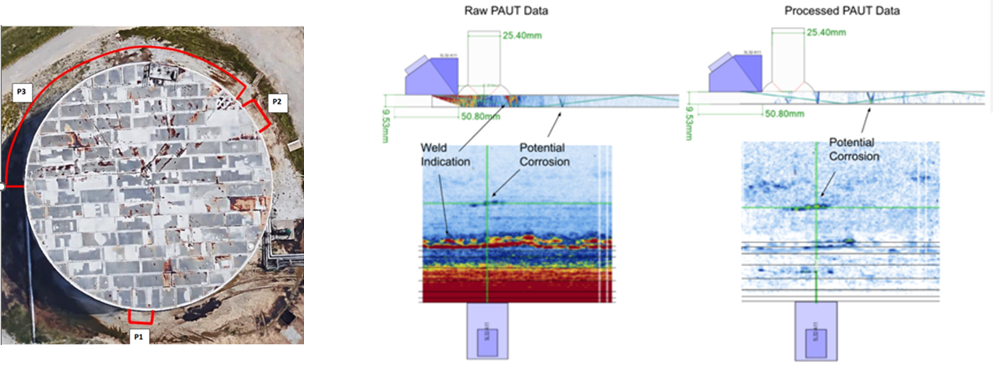

Deployment: Tank Floor Inspection (Shannon Information Processing)

- Tank Floor Inspected with Multiple-Skip PAUT technique

- Regions with anomaly highlighted as regions with potential corrosion

- Circumferential location and distance from the shell was reported for each anomaly

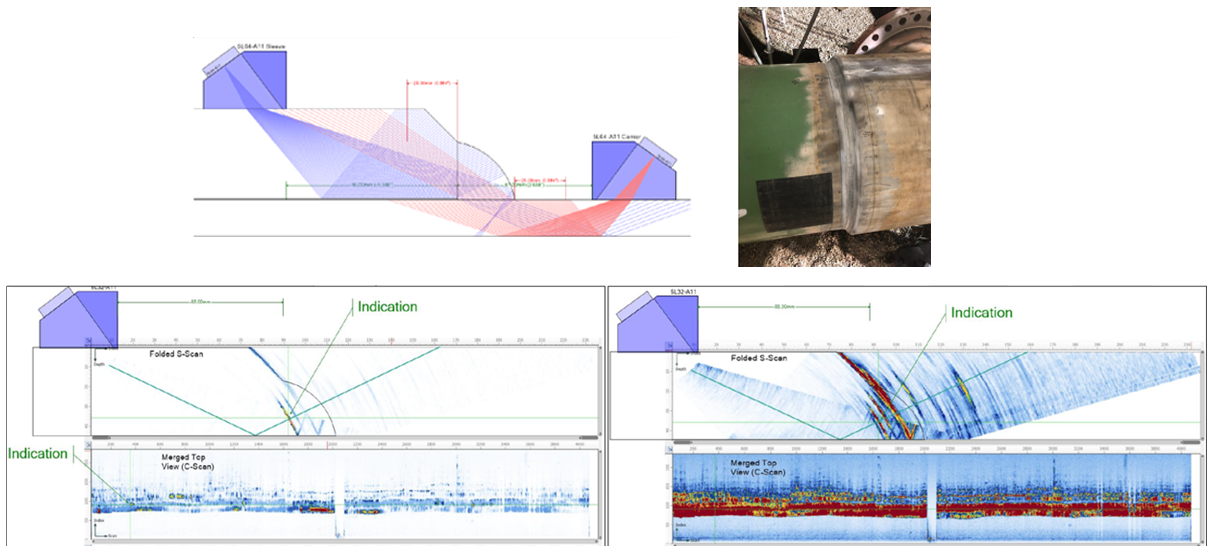

Deployment: Sleeve Weld Inspection (Shannon Information Processing)

- Major reflections from weld obscure small LOF flaws

- Potential for mis-identifying geometry as flaws or flaws as geometry

- LOF defects much easier to identify after applying Shannon Information Processing

- Analysis significantly faster, less prone to false calls

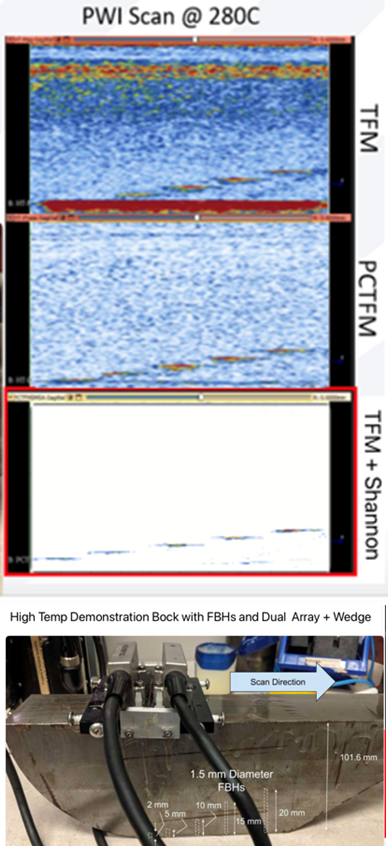

Shannon Information Processing: Vessel Inspection at High Temperature

- Developed prototype system for on stream inspection of heavy walled vessel (temperature above 200°C)

- Designed custom wedge to withstand high temperature (up to 350°C)

- Tested on 4” block with small FBH holes drilled to various depths heated to 280°C

- TFM imaging very noisy, shallowest target merged into backwall, PCI image improved but still noisy

- TFM with Shannon Info processing on signals plus thresholding gives best detection of simulated flaws

| Highlights of Projects | ||||

|---|---|---|---|---|

|

Phase Coherence Imaging (PCI) Based Applications Anomaly Detection UT Data Analysis Based Applications FMC/TFM Based Inspection Applications Phased Array Based Inspection Applications Wind Turbine Blade and Main Shaft Inspection Applications Software Based Solutions | ||||

For more information, email us at

rad@acuren.com

or call (519) 372-1831 and ask for

one of our innovation experts