Wind Turbine Blade & Main Shaft Inspection Applications

Wind Turbine Blade and Main Shaft Inspection Applications

- Wind Turbine Blade Root Inspection

- Wind Turbine Blade Spar Cap Inspection

- Main Shaft Inspection

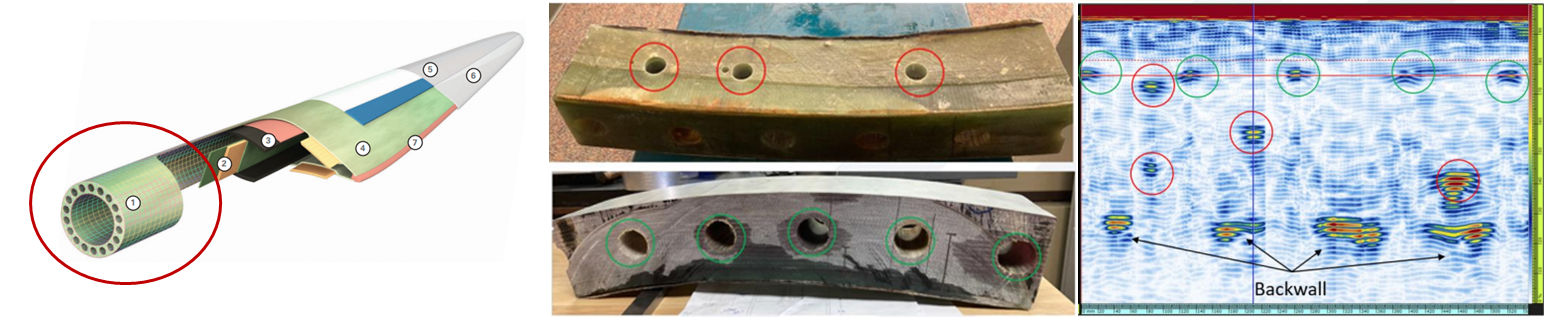

Wind Turbine Blade Root Inspection

- Inspection target: detection of de-laminations/dis-bonds in turbine blade’s root section (Glass Fiber Reinforced Polymer, GFRP)

- Inspection technique developed based on using low frequency conventional and phased array probes & Real turbine blade root section cut out used as calibration piece

- Bolt holes and made calibration targets were detected; Backwall trace showed sound penetration up to 4” from the surface

- Integrated in Acuren Turbine Blade Inspection program

Deployment: Wind Turbine Blade Root Inspection

- Blade Root Sections inspected on site and areas with delamination were market on the blade

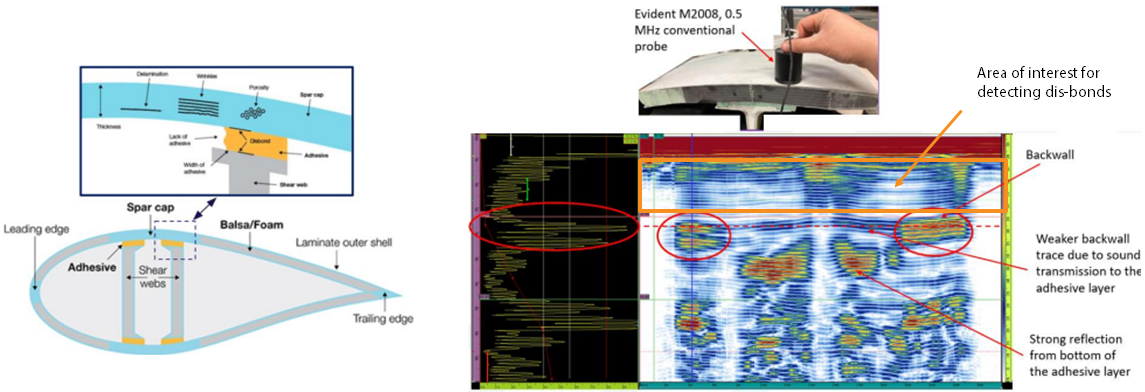

Wind Turbine Blade Spar Cap Inspection

- Inspection target: detection of de-laminations/disbands in turbine blade’s Spar section (Glass Fiber Reinforced Polymer, GFRP and Carbon Reinforced Polymer, CFRP) and adhesive bond

- Inspection technique developed based on using low frequency conventional and phased array probes & Real turbine Spar section cut out used as calibration piece

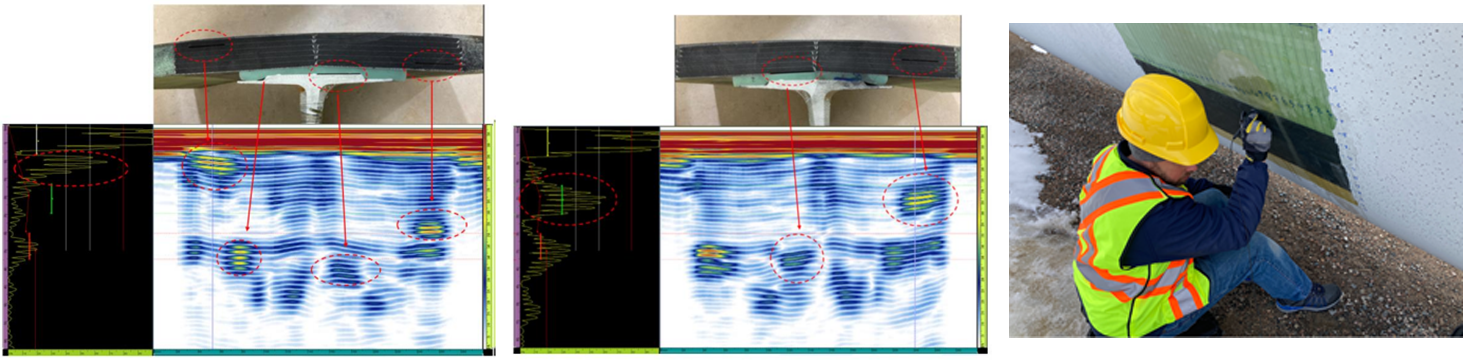

Deployment: Wind Turbine Blade Spar Cap Inspection

- Technique demonstrated detection of dis-bond in both spar cap region and adhesive layer

- Inspection technique Integrated in Acuren Turbine Blade Inspection program

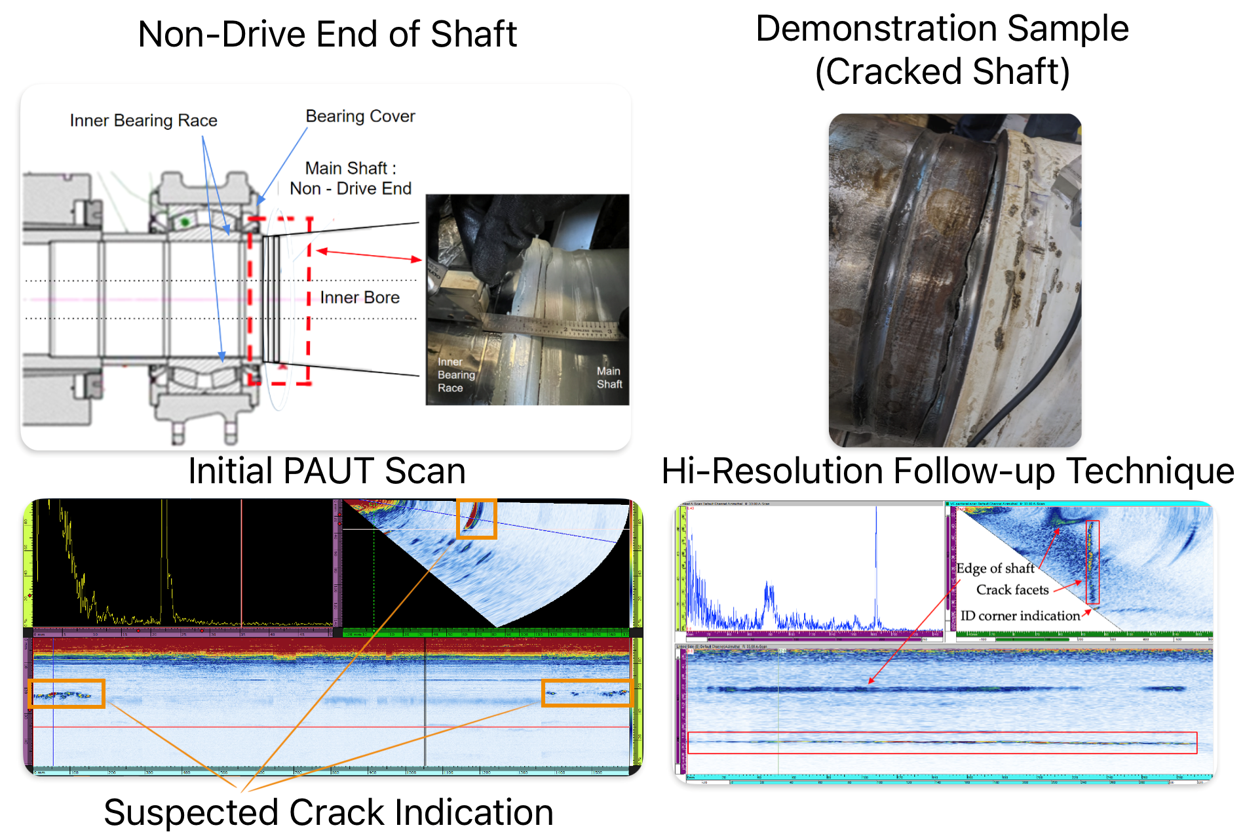

Wind Turbine Main Shaft Inspection

- Technique detecting cracks in main shaft of wind turbines developed for client

- Several shafts tested, one identified as potentially cracked

- More sophisticated, high resolution technique proposed for verification and through wall sizing

- New technique tested on demo sample cracked all the way through, crack facets clearly imaged

- Broader deployment with high resolution technique to be performed in 2024

| Highlights of Projects | ||||

|---|---|---|---|---|

|

Phase Coherence Imaging (PCI) Based Applications Anomaly Detection UT Data Analysis Based Applications FMC/TFM Based Inspection Applications Phased Array Based Inspection Applications Wind Turbine Blade and Main Shaft Inspection Applications Software Based Solutions | ||||

For more information, email us at

rad@acuren.com

or call (519) 372-1831 and ask for

one of our innovation experts